I found Molly Brown in the outside area, where they had put all the items they wanted to "weather". For some reason , It was popular a few years back to have old rusty items in your house and yard for a country effect. I need no country effect at my place. I struggle with rust daily, no thanks. But, tucked in the corner , there she was.

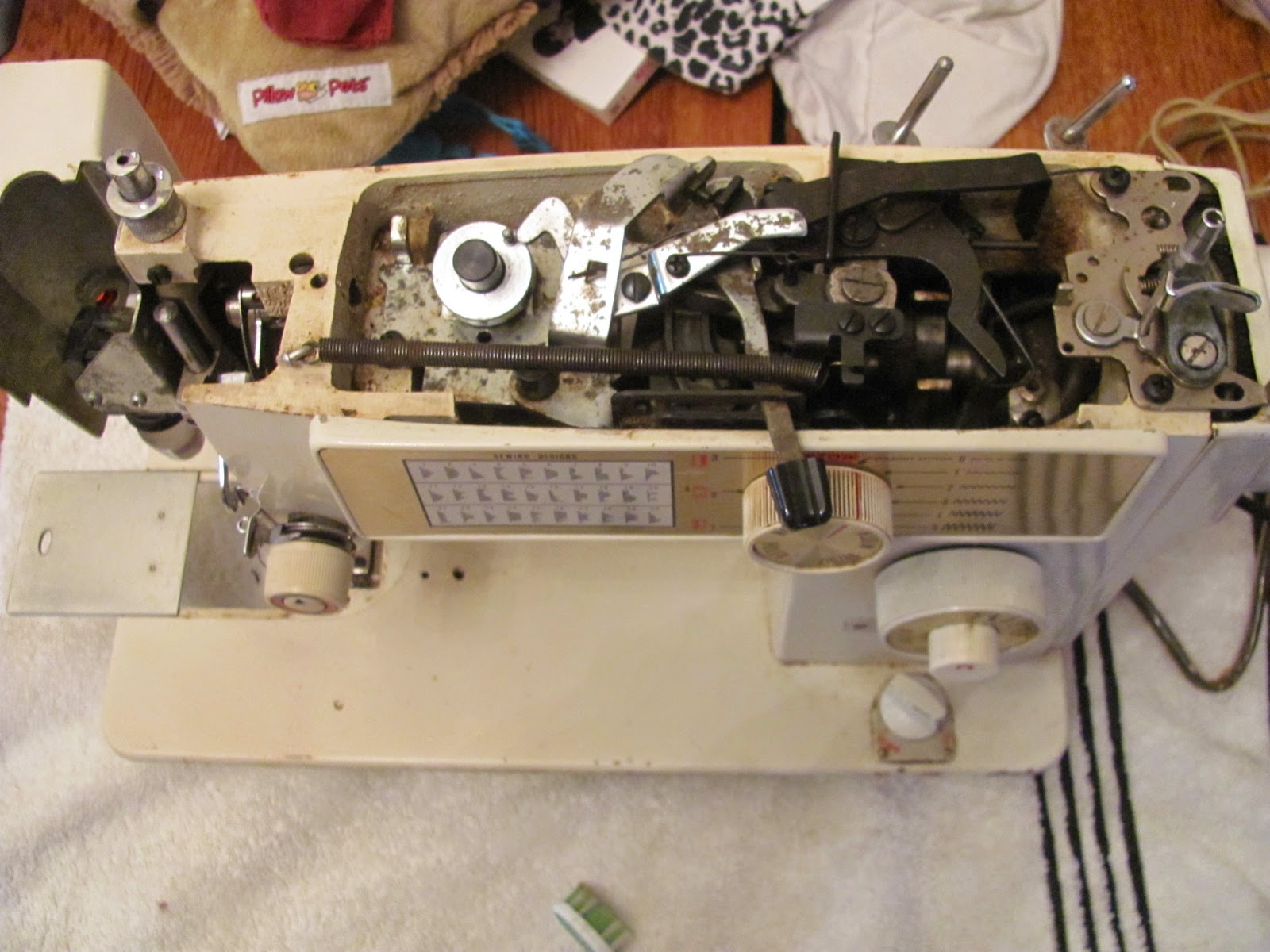

A Singer 27 model treadle head sewing machine. I smiled as I walked closer, knowing this was the project I had been looking for. A measly five bucks and she was mine. Deep down, I knew I would have paid ten for her, just because the condition of Molly was unthinkable to me. To say she was rusty, was putting it a bit mildly.

Holy Cow, is another way to put it.

I first washed her down with water and Mr. Clean. No reason to be gentle. She needed scrubbing. Then, I pulled all her external pieces off. Wheel,plates, everything. I then worked on trying to get some of the rust off using products I already owned. It actually worked pretty well.

From the great folks at Treadle on, and two of my favorite Facebook groups Vintage Sewing Machines and Texas Vintage Sewing Machine Collectors, I found some useful products to help Molly out.

Evaporust. Now, I am no expert, but this does a great job. Not only for Molly , but many of my tools and machines have some rust, it has done a fantastic job of removing it by soaking. It is also biodegradable and safe. The First bottle did a fantastic job, but turned black before the machine was totally unrusted.

Did it get all the rust, No. Since the machine was so bad, I am not blaming the product. Once the product turns black, It is pretty much exhausted. It turned black pretty quickly, I let it soak for about 30 hours. I could not figure out a way to completely submerge the machine. It I do another one, I will get two bottles or 2 gallons , It will make it a lot easier.

My plan was to save for another bottle, and do it all again, It has been two weeks since I washed Molly off and let her sit while the weather did its thing. You need it to be at least 70 degrees for the stuff to work properly.

I bought the other bottle, but when I looked at the machine again, I realized it may not need another, and I oiled her up like she was a 2 dollar whole. Then I gave her a good soak in Liquid Wrench, and put the wheel on. Needless to say, she moves 1/16th of an inch, except for the needle bar. That does not move at all.

I am at the point where I have tried everything to get her to move. She is still frozen . I want to say I have used force, as my patience wore thin, I did result to violence and used a hammer, not just a tack hammer either. I am not proud of this. No avail. No difference. All the parts , when turning the handwheel move together about a quarter of a quarter of an inch, except for the blasted needle bar. That is stationary and stuck. Not with old goo, I am afraid, but with rust. I will try to gently be patient and use my oil and liquid wrench for a few more days. by the weekend, if nothing is happening, I am going back to the evaporust and let her soak in it , especially the needle bar and front gearing.

As of today, she is back soaking in the evaporust, concentrating on the needle bar and the parts that surround it. I am pretty determined. Of course, once I get her moving, I will need to sand down the smash I made on the top of the needle bar from the hammer. Once I soak the front end, I may put her bed back in and maybe the back end too, just to be sure I got everything.